I have been away from the blog for a bit because of other activities. I’ve been busy, and there is only so much time in the day. I do have some writing in the works, but most of my time has been spent working on the house. We have been living here for a year and have made significant progress. Not enough to totally please the Goddess, yet enough to make it livable.

One of my projects was to mount the microwave oven in the kitchen. Leaving it sitting on the counter was never going to fly.

Our century house was never meant to have a big kitchen, which is sad. I am the cook and would love a well-laid-out kitchen. I will never have one in this house and have come to terms with that. However, I think we can still make our kitchen awesome until we can do a full remodel one of these days.

The room has an exposed chimney with bare brick, which looks cool as hell. But the mortar is beginning to crumble a little and we didn’t want to repair it because that would ruin the effect.

What’s better: new brickwork or 100-year-old brickwork?

My stove sits in front of the chimney, and I wanted to mount our big-ass microwave above it. This was a great plan but not an easily executed one. The chimney is beginning to crumble a little, and I didn’t want my microwave falling on anyone sometime in the future.

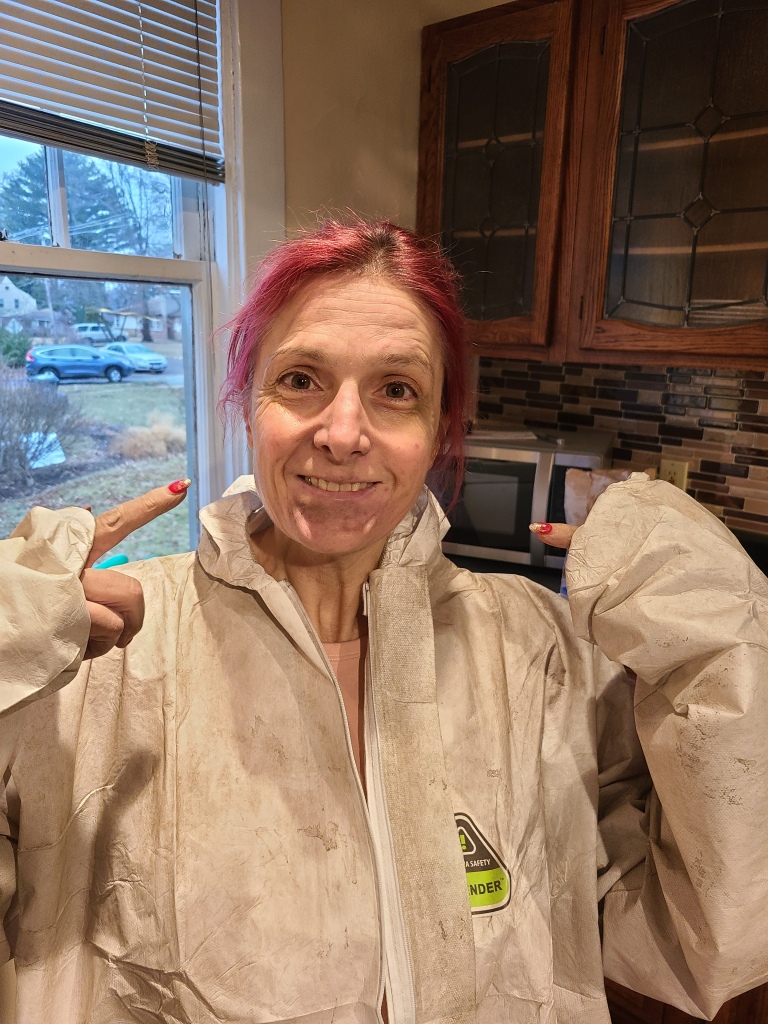

I approached this project as an engineer.

- There was no place for me to support the microwave from above; it would need to hang from the bricks alone.

- There were no commercial solutions that would fit my needs.

- I will have to create something!

- (Evil laugh while rubbing my hands together!)

I purchased some heavy-duty countertop brackets used for marble counters. They were strong enough to support the microwave alone, but the bricks were not. I would need to provide much more of a connection to the chimney. To give the brackets something to connect to, I purchased some steel strips and drilled them to match the hole pattern of the brackets. I wanted plenty of connection points with the brick.

Old brick has a tendency to crack easily, which is BAD! And I also avoided drilling into the crumbly mortar, I couldn’t rely on it to hold over time. I carefully drilled into the bricks and used anchor bolts to attach the brackets to the wall.

Then together, we hung the microwave and pushed the stove back into place. I still need to vent the fan somehow – venting back into the room doesn’t really do much.

I think it looks amazing. I am very happy with the results.

And, of course, so is the Goddess!